Repmold: The Future Where Nothing is Ever Worn Out

Imagine a world where a cracked smartphone screen repairs itself in minutes. Where the sole of your favorite running shoe, worn thin from miles of pavement, gradually thickens back to its original form overnight. Where a chipped car bumper slowly, seamlessly, flows back into its perfect shape without a trip to the body shop.

What is Repmold?

Repmold (a portmanteau of “Replicate” and “Remold”) is a hypothetical class of self-healing smart materials. Unlike current self-healing polymers, which are often limited to repairing minor scratches or require specific external triggers like heat, Repmold envisions a more profound and autonomous capability.

The core idea is a material embedded with a synthetic, nano-scale “instruction set” and the means to carry it out. Think of it as a material with a perfect memory of its original, undamaged state and the ability to actively rebuild itself to match that blueprint.

How Would It Work? The Theory Behind the Magic

While purely conceptual, Repmold would likely function through a multi-faceted approach:

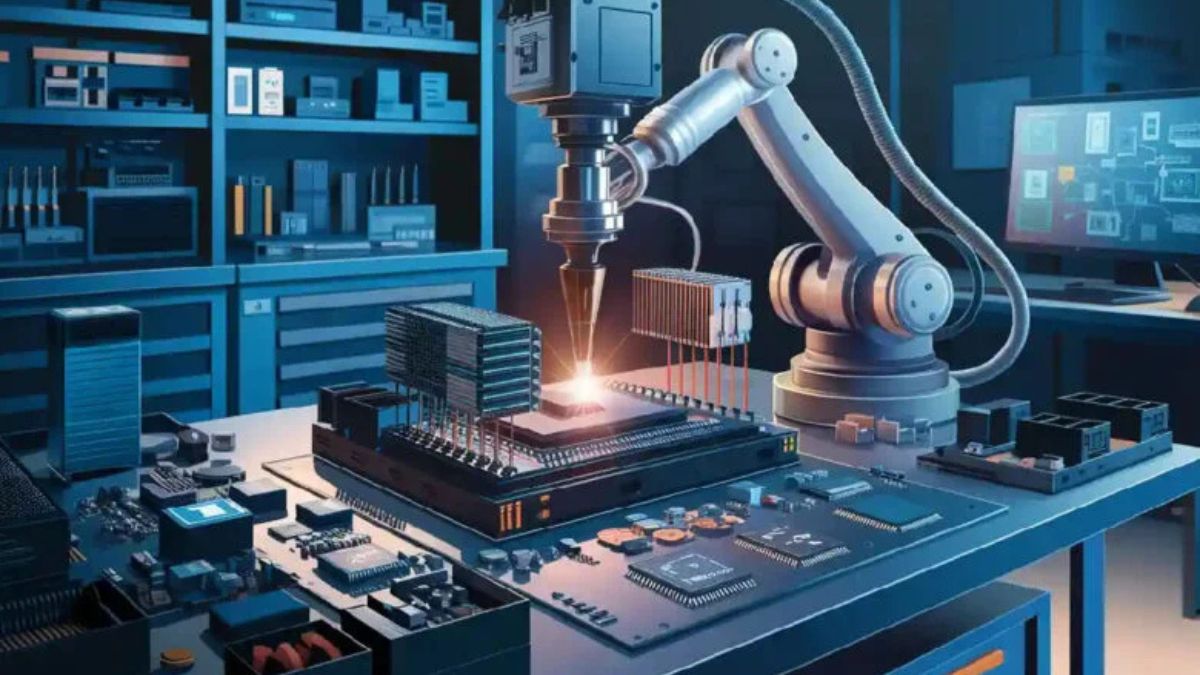

- The Nano-Scale Network: The material would be laced with a vast network of nanoparticles or microcapsules. These aren’t just repair agents; they are sophisticated units containing raw material monomers, a power source (perhaps harvesting ambient energy), and a tiny processor.

- The Structural Blueprint: Each Repmold object would contain a digital map of its intended structure—a kind of “material DNA.” This blueprint is stored throughout the network, allowing any section to know what it should be.

- The Damage Assessment: Using micro-sensors, the material would constantly monitor its integrity. Upon detecting a breach, crack, or wear, the local network would assess the extent of the damage against the stored blueprint.

- The Rebuilding Process: Here’s the fascinating part. The nanoparticles would then work in concert, releasing raw materials and using energy to catalyze a rebuilding process. This could involve:

- Flow: Liquefying nearby stored material and guiding it to fill gaps.

- Replication: Using the surrounding undamaged area as a template to precisely reform broken molecular bonds.

- Curing: Solidifying the new material seamlessly into the existing structure.

Potential Applications: A World Transformed

The implications of Repmold technology would be nothing short of revolutionary across every industry:

- Consumer Electronics: Say goodbye to cracked screens and broken casings. Devices could become more durable and long-lasting, drastically reducing electronic waste.

- Automotive and Aerospace: Car bodies, airplane wings, and critical components could self-repair from minor impacts, stress fractures, and wear, leading to unprecedented levels of safety and longevity.

- Infrastructure: Bridges, roads, and buildings made with Repmold-enhanced concrete or alloys could continuously maintain their structural integrity, detecting and repairing stress cracks before they become catastrophic.

- Medicine: The most profound impact could be in biotech. Imagine prosthetic limbs that self-adjust for comfort, or biocompatible implants that repair themselves inside the body, eliminating the need for replacement surgeries.

- Sustainability: This is Repmold’s crown jewel. By creating products that last decades instead of years, we could fundamentally disrupt the “take-make-waste” economy and move towards a truly circular model where repair is automatic and built-in.

The Challenges and Ethical Considerations

Of course, such a powerful technology comes with significant hurdles and questions:

- Energy Consumption: The process of breaking and forming molecular bonds is energy-intensive. Where would this energy come from? Could it be efficient enough to be practical?

- Material Limitations: Could a single material system be complex enough to replicate the intricate combination of plastics, metals, and glass found in a modern device?

- The Control Problem: How do you stop the repair? Would a Repmold object ever mistakenly “over-grow” or repair itself in an unwanted way?

- Economic Disruption: Industries built on manufacturing replacements, repairs, and maintenance would need to completely reinvent themselves.

- Security: If a material can be reprogrammed, could a “Repmold virus” be used to deform critical infrastructure or products?

The Road Ahead

Repmold remains firmly in the realm of science fiction, a compelling thought experiment that pushes the boundaries of materials science, nanotechnology, and AI. However, it serves as a crucial North Star for researchers in the field of self-healing materials.

Each incremental advance—a plastic that heals itself under UV light, a concrete that seals its own cracks with bacteria—is a step toward the Repmold ideal. It challenges us to think bigger: not just to create things that are less breakable, but to create a world where breaking is merely a temporary state, soon to be followed by a silent, effortless return to wholeness.